Between May 27-29, a visit of the European Commission delegation took place in the North-East Region. We were honored to host and participate in productive discussions, receiving valuable feedback that will help us improve and grow our local communities. It was three days with a busy agenda, with meetings, meetings and project visits, all contributing to shaping a positive image of our region.

Sofia Alves, director of DG REGIO for Urban Policies and Cohesion, Iva Maric and Irina Sofletea, program managers of DG REGIO, visited successful projects financed by ROP 2014-2020 and participated in the fourth meeting of the Monitoring Committee of the Regional Program 2021 -2027.

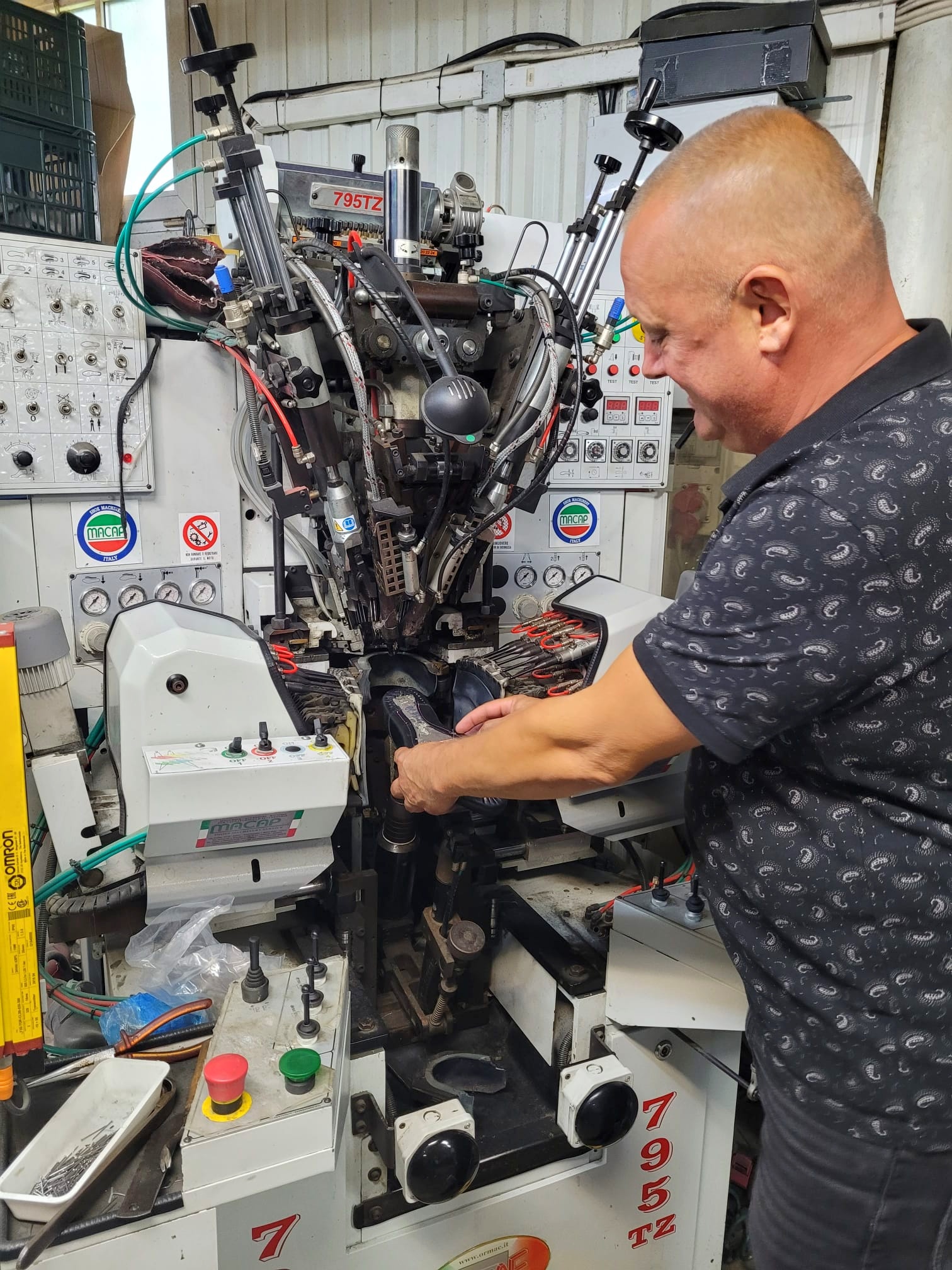

On the first day, Sofia Alves, accompanied by Vasile Asandei, General Director of ADR Nord-Est and George Turtoi, MIPE director, spoke with two of the 2014-2020 POR beneficiaries: Manifatture Neamț and ZenZia Glamping. She listened with interest to the story of business development with the support of Regio and gave valuable advice regarding long-term development, both financially and sustainably.

After visiting the headquarters of MA within the North-East RDA and getting to know the management team of the Program, the delegation participated in the official launch of the ROStartup Association at the Rubik Hub headquarters, in Piatra Neamț.

The representatives of the European Commission were also present the next day, on May 28, at the meeting of the Monitoring Committee for the North-East Regional Program 2021-2027, together with members and observers.

„I want to congratulate the North-East ADR team for all the work done within the North-East Regional Program and for the development of the innovation ecosystem in the North-East Region. I also congratulate you for the inspiration to regulate the Romanian startup ecosystem at the national level and for the establishment of the ROStartup Association. We are happy about the concern for increasing the administrative capacity, not only within the Agency, but also among the beneficiaries and potential beneficiaries of the Regional Program„, said Sofia Alves, Director of DG REGIO.

On Wednesday, May 29, before departure, the delegation visited some of the emblematic projects in Iași, also financed by ROP 2014-2020: the old Roman Catholic Cathedral „Adormirea Maicii Domnului”, Origyn Fertility Center, MAVIS Technological Transfer Center within the University of Medicine and Pharmacy „Grigore T. Popa” and building E, newly renovated with European funds, of the „Alexandru Ioan Cuza” University.

INTERES PUBLIC

INTERES PUBLIC

During the final conference of the project, which was organized on the 24th of January 2024 in Brussels, with the help of the NE RDA Brussels Office, MEDIC-NEST Meta-Cluster in Precision Medicine was officially launched. MEDIC-NEST founding members (Imago-Mol Cluster – Romania, MEDVIA – Belgium, HBIO – Greece, SIVI – Spain) had the pleasure to welcome in the newly formed alliance the partner clusters:

During the final conference of the project, which was organized on the 24th of January 2024 in Brussels, with the help of the NE RDA Brussels Office, MEDIC-NEST Meta-Cluster in Precision Medicine was officially launched. MEDIC-NEST founding members (Imago-Mol Cluster – Romania, MEDVIA – Belgium, HBIO – Greece, SIVI – Spain) had the pleasure to welcome in the newly formed alliance the partner clusters:

It was a complex event, with multiple panel discussions (covering topics from textiles, bioeconomy to regional programs for cluster financing), presentations and pitches, matchmaking sessions, with the aim of promoting interregional collaboration, sharing best practices for encouraging and facilitating internationalization and cross-border cooperation.

It was a complex event, with multiple panel discussions (covering topics from textiles, bioeconomy to regional programs for cluster financing), presentations and pitches, matchmaking sessions, with the aim of promoting interregional collaboration, sharing best practices for encouraging and facilitating internationalization and cross-border cooperation.