Reporter REGIO: episode 19

From honey sachets to robots, with Regio support

Success stories, possible with the support of Regio Nord-Est 2014-2020

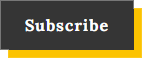

In a world of continuous evolution and change, where technology and innovation blend to reach unprecedented heights, individuals who not only adapt and keep up with the times but embrace them with enthusiasm stand out. Dacian Popa is an economist but an automation enthusiast at heart. He founded a company that provides automation solutions for technological processes using robots, primarily in the product packaging field. This is the story of Micropack Automatizări from Iași. With a recent project funded through the 2014-2020 Regional Operational Program, with a total value of 240k euros, of which 185k euros was non-repayable, Dacian believes that his company’s competitiveness has significantly increased. Now, he stands shoulder-to-shoulder with giants in the field of robot automation.

From packaging honey sachets to robots

In 2008, after working for other companies, Dacian felt he was ready to embark on the path of entrepreneurship. He imported a machine from China designed to perform a simple task: package honey in sachets, known as micro packaging. However, the machine didn’t work. While trying to fix it, he met his future business partner, an automation expert who helped him get the machine running. Both realized they had a knack for this and, most importantly, a passion for it. They became partners, opened a mechanical processing workshop, and began building new primary packaging machines. They realized that every product requires packaging: first comes primary packaging, followed by secondary packaging or boxing, and then tertiary packaging or palletizing. They could provide all of this to their customers with in-house machines. They successfully exploited this niche for ten years.

Ten years later, they received a larger contract for packaging that included a robot. This is when they were introduced to robotics. It was a turning point. „We believed this was the path for large-scale work. It was an important year, full of achievements. On the one hand, the numbers looked good. On the other hand, my partner didn’t want to embark on large-scale projects involving robots, as they come with risks. That’s when we decided to go our separate ways. We continue to collaborate in the same field, we remain friends, but we’re no longer business partners,” Dacian recalls.

Automating packaging processes

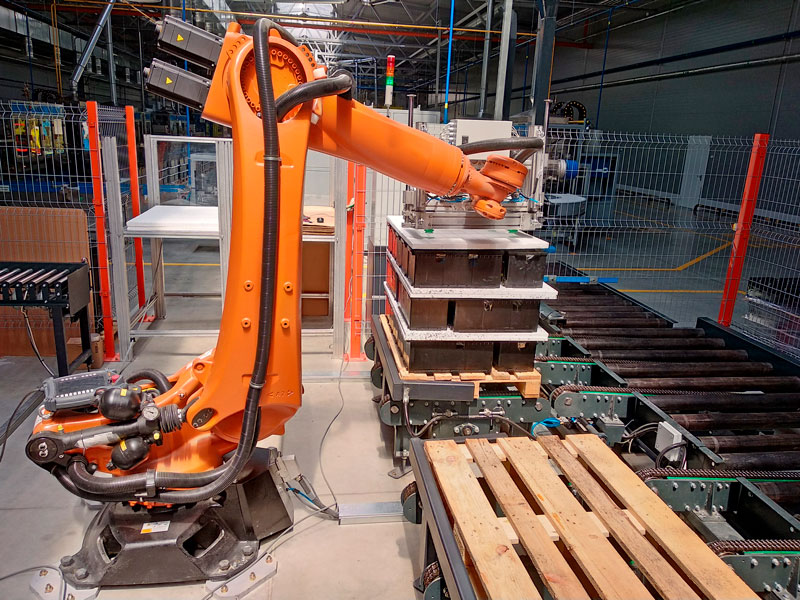

In 2019, Dacian returned to primary packaging for customers, but the idea of the previous year showed him the right direction. He started brainstorming and offering solutions to his customers, especially those in the food industry, to reconfigure existing technological routes through process automation. They aimed to propose automation solutions to companies and increase productivity without the need for more employees. „A robot won’t replace a dedicated machine but will enhance its capabilities. We let robots handle simple and repetitive tasks or tasks that can affect human health. Many times, automation cells protect people from tasks that could harm their health, such as repeated bending, heavy lifting, or working in uncomfortable environments like refrigerated storage or places with high temperatures. Equally important is the fact that intelligent automation solutions reduce the space used for different processes by half,” says Dacian Popa.

Significant partnership with a robot automation giant

In any industry, there are key players in the field of robots and automation. One of these names, Kuka, proposed a partnership in 2020. Kuka is an international automation conglomerate with a turnover of approximately 4 billion euros and around 15,000 employees. „One of the core verticals in robotics is packaging, and it turns out we are good at it. Our partnership with Kuka demonstrated that we excel at what we do. Among the five integrators in the country, we specialize in the automation of packaging processes,” Dacian says. So, Kuka provides the robots, while Micropack handles the automation for packaging and goods handling.

Software and hardware equipment through the 2014-2020 ROP

Because resources were limited but needs were unlimited, Dacian applied for a project to purchase innovative technology for designing and manufacturing machinery with non-repayable funding from the 2014-2020 Regional Operational Program. Among other things, he bought specialized software for designing, building, and virtually simulating manufacturing processes, integrating various equipment: an industrial robot for cutting tables, a laser beam for that robot, a CNC machine, a vision chamber with a safety laser system, and a 3D printer that he’s particularly proud of. „We have a major advantage. With the help of these funds, we’ve equipped ourselves with both software and hardware that will help us remain competitive in the future. The software for design has reduced our robot programming effort by 40%. We also have a vision chamber that provides coordinates to a robot to identify, locate, grip, and sort various products, and it can be used for eight cascading robots. The 3D printer we purchased didn’t even exist three years ago. We were visionary when we included it in the project. This printer can create airplane parts. It is used in U.S. military units. It fulfills my dream as an entrepreneur of many years: it tells me the cost and delivery time before pressing the button,” Dacian enthusiastically describes the equipment that greatly aids his business. He believes that without these funds, it would have been much more challenging, but they have opened many more doors and opportunities for him.

Waste sorting with robots and an ERP system

As for future plans, Dacian and his team dream of taking their waste sorting solution outside Romania. Even though the idea belongs to Canadians, he wants the automation solution to be his own. Sorting errors are common when collecting or storing recyclable materials, either due to user carelessness or lack of information. Robots can analyze and sort waste much faster than humans. By speeding up the sorting process of recyclable materials, the total amount of materials that can be efficiently recycled and reused is significantly increased. Additionally, as a future project, the company aims to digitize its operations with an ERP system. Of course, a solution for digitization is available through the „Digital Transformation of SMEs Focused on Increasing Digital Intensity” initiative in partnership with the World Bank.

He relies on Peter Drucker’s motto, which says, „The best way to predict the future is to create it.” Dacian works with big names in the food industry and leverages all of the company’s resources for these projects. He can transform manual packaging processes into robotic processes in any field and even offers rental solutions for robotic automation. At the moment, Micropack Automatizări has clients on a waiting list for the next 20-30 robots. He acknowledges that many entrepreneurs consider robotics more of an expense than an investment, but Dacian aims to prove that, in the long run, it’s a win, especially considering the acute labor shortage in the job market. He also notes, „Once you start working on automation, you find professional fulfillment. It’s like a bug. We’re never bored. We come to work as if it’s play.„.

Reporter REGIO is a new North-East RDA initiative, which focuses on promoting the successful projects of our beneficiaries, projects that have managed to stand out by bringing added value and impact to the community. At a time when negative news predominates, we offer you beautiful but true stories for reading, meant to strengthen the belief that „it is possible”! Be part of the story!

Are you a Regio beneficiary? Let us tell you the story.

Contact us for details at info@adrnordest.ro

INTERES PUBLIC

INTERES PUBLIC