Reporter REGIO: episode 22

When the love for animals intertwines with an entrepreneurial spirit, REGIO comes to the rescue!

Success stories, possible with the support of Regio Nord-Est 2014-2020

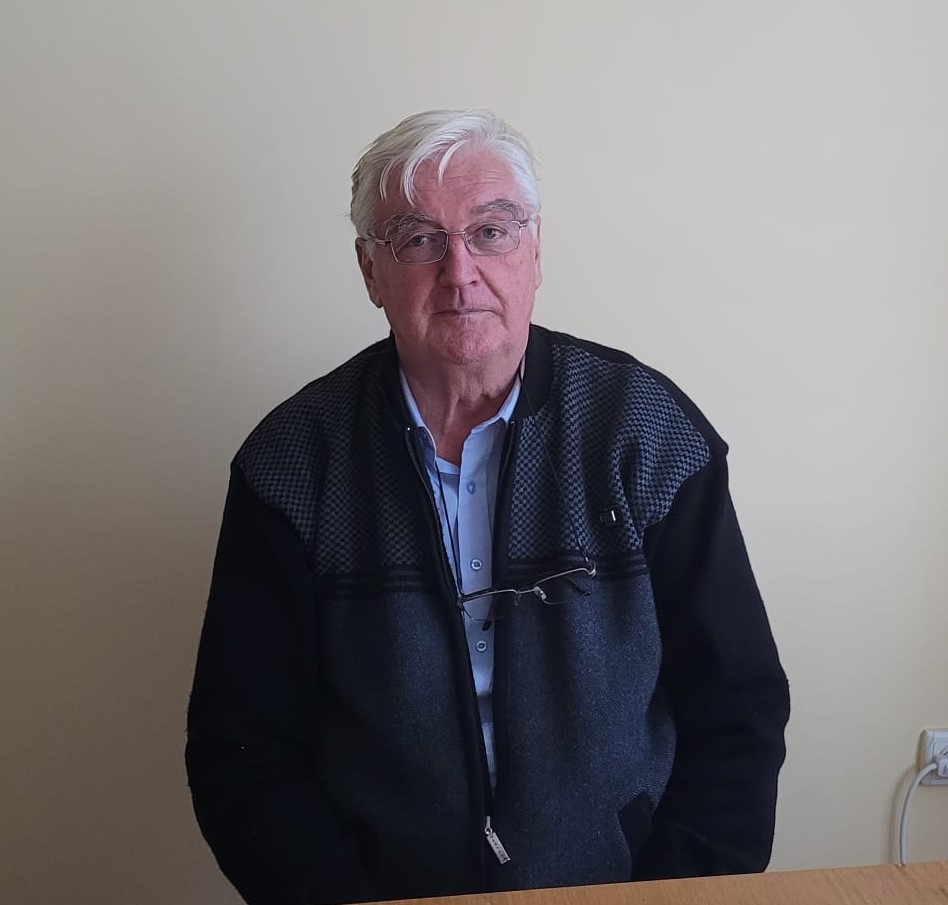

Growing up in a village in northern Moldova, alongside grandparents who taught him to love and appreciate animals, Dumitru Fodor pursued an education in a high school with an agricultural profile and later attended the Faculty of Veterinary Medicine of Iași. After nearly 10 years of experience in other companies within the same field, he established his own distribution company for veterinary medicines. In 2012, Dumitru Fodor founded Vetro Solutions in Iași. Following the establishment of the distribution part of the company, he envisioned venturing into production. Now, a decade later, he acknowledges that he wouldn’t have had the courage to delve into veterinary medicine production at that time without the support of European funds. The non-reimbursable financial assistance from the Regional Operational Program 2014-2020 amounted to 4.5 million lei, contributing to a total project value of 7.5 million lei. With this funding, he established a veterinary medicine production unit that achieved a turnover of 63 million lei and employed 82 people in 2022.

From distribution to production

Dumitru Fodor has had a lifelong love for animals and knew he would build a career around them. He started working in a veterinary pharmacy in his third year of college. Subsequently, he worked in the distribution of veterinary medicines, in time becoming a manager in a corporation. After accumulating experience in other companies, he opened his own distribution company in 2012. The entrepreneur in me was still trying to emerge, even though I was employed in other companies. I leaned towards distribution for a very simple reason: as a veterinarian in a clinic or pharmacy, you take care of animals, but it’s a limited scope. I wanted to do something more, to influence the well-being of animals. Thus, I focused on distribution. After establishing this chapter, I thought, ‘What’s next?’ I looked at the market in Romania, saw what was happening, and noticed that there is room for production. I knew how many products came from abroad, so why not make them here? thought Dumitru Fodor.

He received much encouragement to move forward in this field, especially from members of the Romanian Business Leaders group, of which he has been a part for several years. When he shared his idea and what he wanted to develop in production, the advice pointed towards accessing European funds. There are many people with businesses large or small that you talk to. When I had the idea and started discussing it with them, they told me about the available funds and what they were for. That’s when I started studying and saw that there were funds for my area of interest. I’m the type of entrepreneur who likes to study before starting a project., says the veterinary doctor.

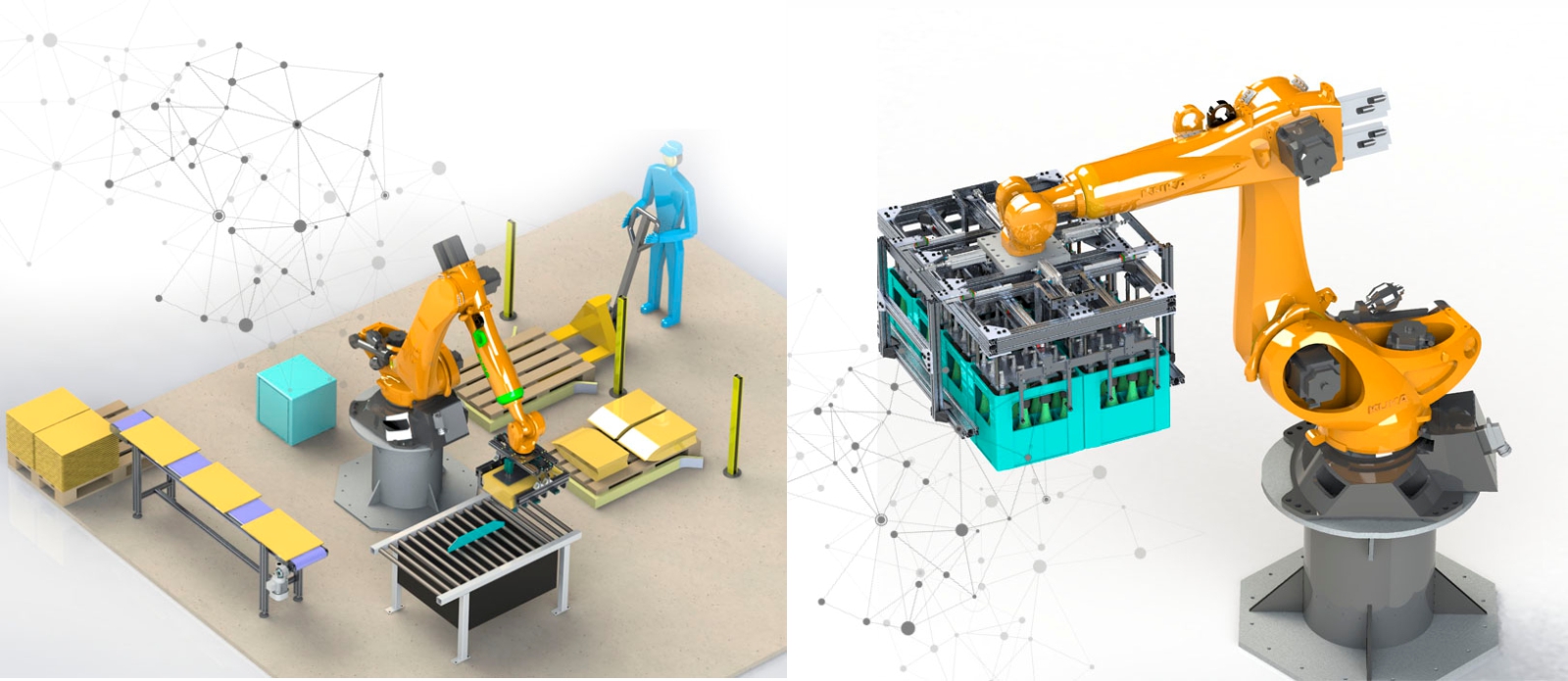

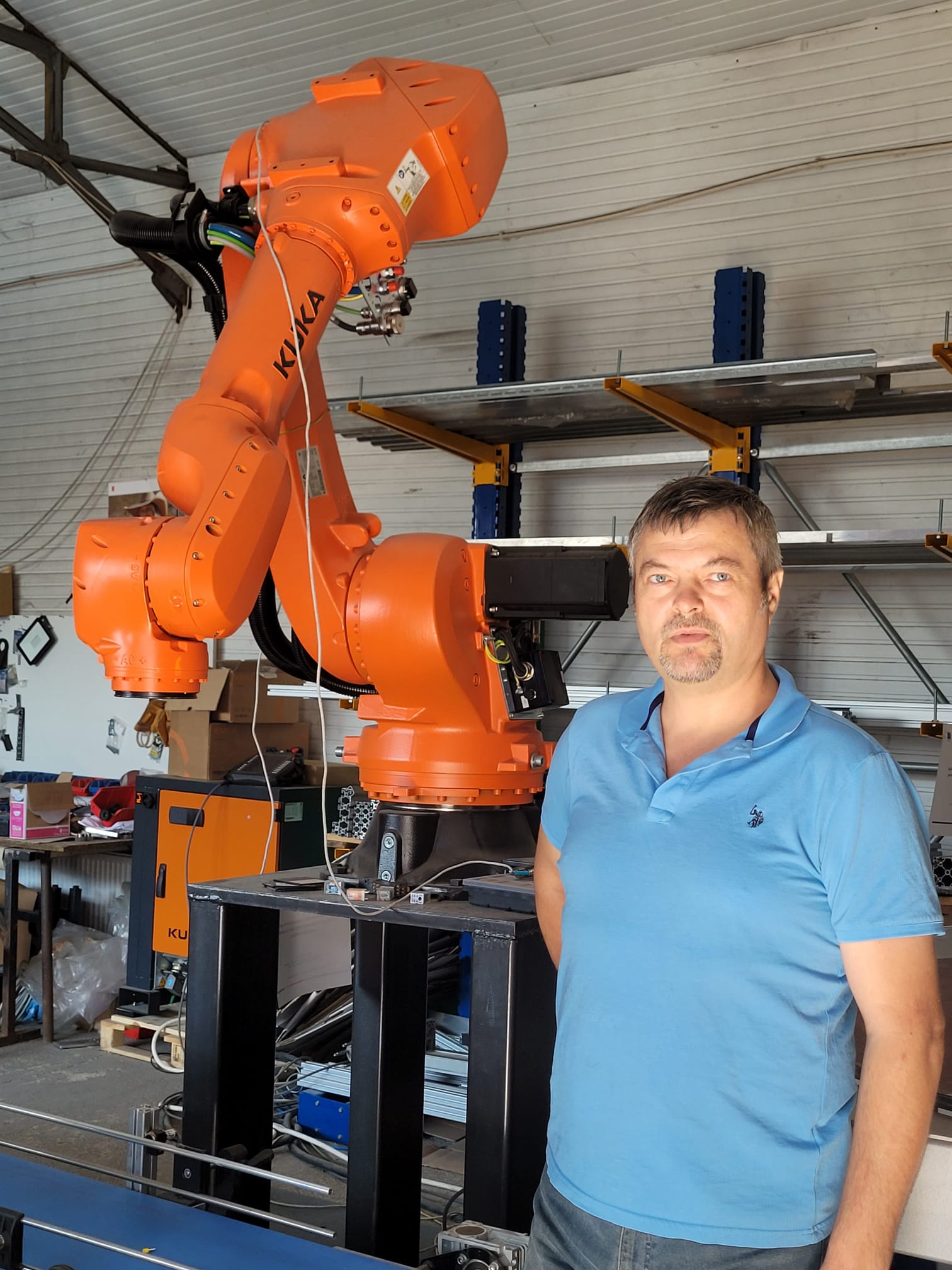

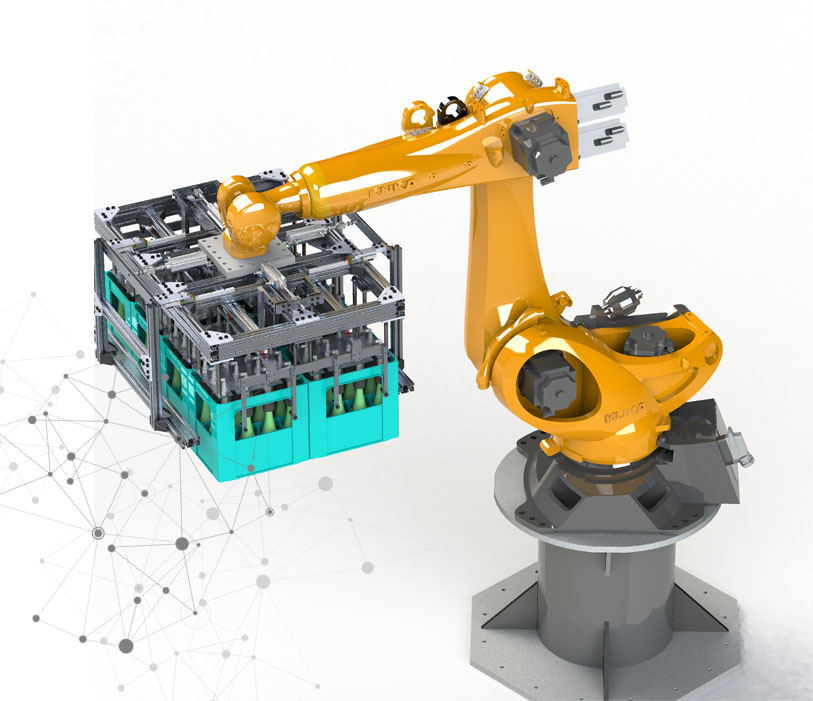

Production and digitization

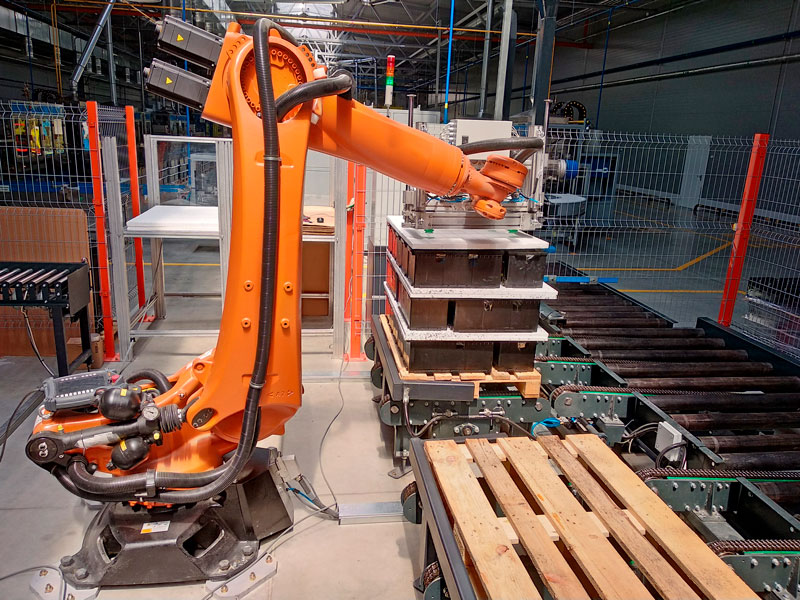

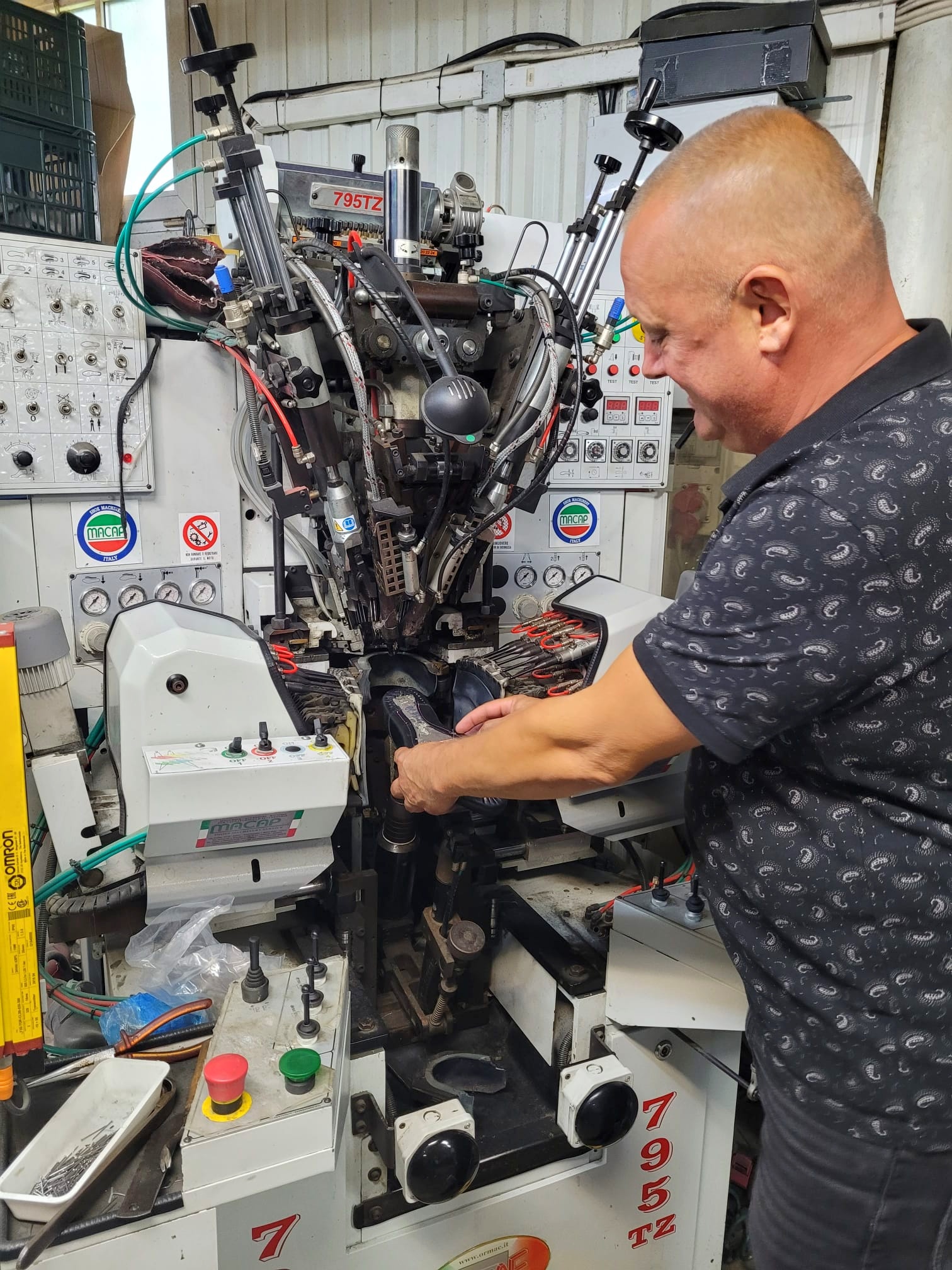

In his plan, Dumitru had two areas of development: one in production and one in digitization. Both materialized as projects funded by European funds and were implemented in parallel. The two projects were financed by the European Regional Development Fund: one through the Regional Operational Program 2014-2020 and one through the Competitiveness Operational Program 2014-2020. The digitization project resulted in a marketplace that directly connects producers, veterinarians, and pet owners. The second project, a factory for the production of veterinary medicines, received operating authorization in November 2021. All the equipment necessary for the production process in this factory was acquired through the Regional Operational Program 2014-2020. Dumitru Fodor states that the entire investment amounted to 3 million euros, with the building being purchased separately. It was a sustained effort to have a factory the way we wanted it. The investment was a little higher than we initially thought. Since it involved medicines, we paid a lot of attention to quality. We established a laboratory and then launched our own brand so that we could sell under this brand, says Dumitru Fodor. The medicines produced in the factory in Iași are sold in Romania under the adVet brand, created specifically for products manufactured by Vetro Solutions.

Partnerships with veterinary faculties

In the production of veterinary medicines, there is a lot of research involved. Initially, they conducted their own research, after which they followed the example of other partners and entered into external collaborations. The Faculty of Veterinary Medicine of Iași supported them with research for several products, as did the Faculty of Veterinary Medicine of Bucharest. The production part is not difficult, but a lot of documentation is needed, and it takes time. If you want quality products, you have to document properly. We work with the specialists we have in our company, but we also turn to those who have more information and expertise than we do, says the veterinary doctor.

Pandemic, an advantage

Dumitru Fodor recounts that his experience with European funds was very positive. Not even the pandemic slowed down the course of investments during that period; on the contrary, it turned into an advantage for them. Veterinarians did not close their offices, and farms did not lock their doors, so veterinary services continued to operate, and businesses in this sector even experienced growth. This was also the case for Vetro. We started implementation in January and in March the lockdown was declared, but it turned out to be an advantage for us. We managed to achieve a lot during the pandemic, says Dumitru.

Without European funds, we wouldn't have been able to start

As for future plans, Dumitru Fodor wants to focus on consolidating the adVet brand and expanding sales. We are moving forward with distribution; what we produce must also be sold. We have considered internationalization, but until we settle very well at home, we won’t move forward with that, thought. Proposals come from abroad, but I believe we have work to do here, in Romania. Afterward, we’ll look beyond borders. That’s the focus now: production and distribution in a digitized company, says Dumitru Fodor.

He also states that without European funds, we wouldn’t have been able to start.The writing of the project and the business plan took about two years. He treated the entire process seriously, and the results did not take long to appear. He even had someone hired in the company who only worked on European-funded projects since 2017. „As long as there are funds that help us increase our competitiveness in the European market, why not take them? If it weren’t for the funds, at that time, I wouldn’t have started production. It’s a significant advantage to be financed by someone, to receive a vote of confidence without having to pay the money back, concludes veterinary doctor Dumitru Fodor.

Reporter REGIO is a North-East RDA initiative, which focuses on promoting the successful projects of our beneficiaries, projects that have managed to stand out by bringing added value and impact to the community. At a time when negative news predominates, we offer you beautiful but true stories for reading, meant to strengthen the belief that „it is possible”! Be part of the story!

Are you a Regio beneficiary? Let us tell you the story.

Contact us for details at info@adrnordest.ro

INTERES PUBLIC

INTERES PUBLIC