Reporter REGIO: episodul 21

A bridge between family, business, and European funds, designed with REGIO support

Success stories, possible with the support of Regio Nord-Est 2014-2020

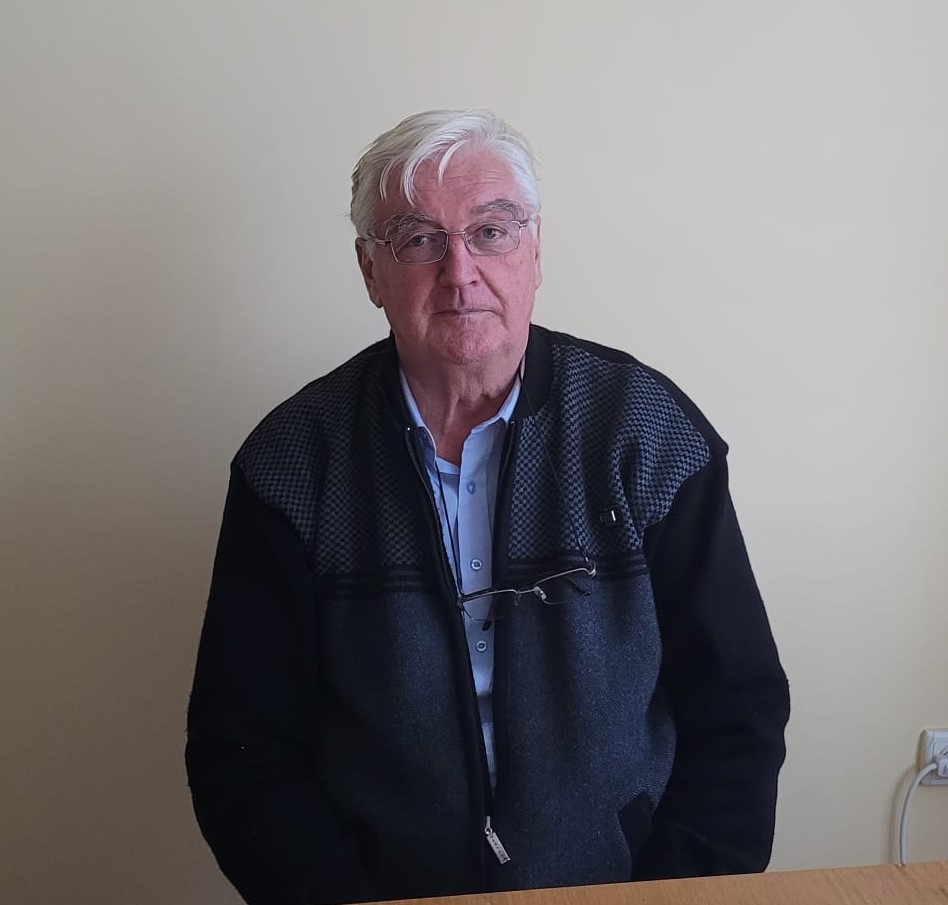

Petru Popa turned his profession into a passion and his passion into a business, specializing in road and bridge design since ’78. He graduated from the Polytechnic Institute of Iași City in „Railways, Roads, and Bridges” following in the footsteps of his father who worked in the field. He established his first design firm in 1991 in Piatra Neamț City, renaming it Pemora SRL ten years later. Petru Popa has two daughters: Mona, a university professor in Canada, and Raluca, who works alongside him in design and is set to take over the company’s leadership at some point. Despite being retired since 2015, he stays active doing what he has loved throughout his life: design. The €40.000 obtained through the Regional Operational Program 2014-2020 has helped the team evolve, providing high-quality and precise services with the help of advanced equipment acquired through the project. Petru Popa states that a year after completing the project, the turnover increased by approximately 20%, and European funds played a significant role in this growth.

Design, project verification, expertise, and laboratory work

SC Pemora SRL is a family business with five employees: Petru, his younger daughter Raluca, his son-in-law, and two other experts. This team covers all phases of road and bridge project design, technical expertise, and laboratory services for construction testing. Both Petru and Raluca hold doctoral degrees in this field, and only seven experts have similar qualifications in Moldova. There are only two construction testing laboratories in the entire North-East Region, ensuring continuous activity for Pemora SRL. Even during the pandemic, they did not stop working. Their main clients are public institutions, but not exclusively. Pemora SRL designed the road and platform sections for 20 Dedeman stores nationwide, as well as Shopping City Piatra Neamț and other commercial complexes across the country. They also worked on roads and bridges throughout Romania (Baia Mare, Cluj, Vâlcea, Constanța, etc.). Their projects include the pedestrian overpass at Pietricica, all-around intersections recently built in Piatra Neamț, and the replication of the Ozana bridge in Târgu Neamț, spanning 100 meters. „Our advantage is that we operate in multiple areas: design, project verification, expertise, and laboratory work. There are times when projects come from all directions. We do not complain; we have experience and know how to handle them,” says Petru Popa.

They submitted the project themselves

The need for investment in equipment arose naturally. They desired high-performance, state-of-the-art equipment to diversify their services, provide clear work, and improve graphics. „Initially, we wanted to secure a large sum, €200,000. However, we did not factor in the VAT, and we realized that the amount we had to contribute was higher than we could afford. We would have had to take out a bank loan. I am not a fan of loans. Ultimately, we stretched ourselves as much as our blanket allowed, around €40,000. It proved to be a good decision over time,” recounts Petru Popa. However, this decision meant they would be left without a project consultant. Initially, when they agreed on €200,000, with a 3% consultancy fee, reducing the amount to €40,000 also reduced the percentage. „We were left hanging. But, ultimately, it was beneficial for us. That’s when Raluca started studying the program intensively, knocking on doors to ask questions, and calling the ADR Information Office. She read everything possible about funding. She coped. For us, it was a unique experience. I told my daughter to view this entire learning process as a qualification. You never know where life takes you; it’s good to know everything possible about European funds and the North-East Regional Operational Program. At the same time, the fact that we were no longer dependent on other companies and depended only on ourselves gave us a certain comfort,” says Petru. He must depend as little as possible on third parties, in everything. The fact that they made their project, and purchased equipment that helps them avoid hiring consultants was essential for them. „Not everyone has the same priorities, the same rhythm; there are many factors, and things start to creak. We try to depend as little as possible on others. In design, we rejected many contracts because we lacked capacity. If we could do them ourselves, fine; if not, we refused.„

High-performance technology

Through the project, they acquired a large-format printer, a plotter, two other devices, and a photovoltaic lighting system. Petru says everything went smoothly. „What we got was of quality. Knowing the characteristics, everything went very fast. We spent about €20,000 on equipment from Australia. We were lucky because the supplier provided us with a product with new, improved features at the old price. And in terms of funding, I don’t know if we were the first, but we were certainly among the first. The money came very quickly. Everything happened in 2-3 months. It was a perfect hit,” says Petru Popa.

An essential part of their business is the non-destructive testing laboratory, where the quality of materials used in road and bridge construction is verified. During expertise, there is a phase of field measurements, i.e., tests. Initially, they lacked the necessary equipment and had to rely on collaborators and third-party laboratories. „That’s how we found out that the reality in the field was one thing, and on paper, it was another. And, in the end, when I had to stamp it with my name, it was my responsibility. All these things involve a very high level of responsibility. Some problems can arise; it’s not all sunshine and roses. I have my children with me, and I have to be able to sleep peacefully at night,” says Petru Popa. That’s why a crucial piece of equipment in the project was the laboratory testing equipment. With its help, they check the quality of asphalt mixtures, concretes, aggregates, and soil nature—practically all components of the road. „We have equipment to determine the road from the pit to the final stage. And one of these devices, the one from Australia, which is for road flatness, is the most advanced in the world. Not even the Ministry has one like that. We use it in the mandatory tests conducted for a road section. About 10 tests need to be done, and we perform them at the highest level,” explains Petru Popa.

The Pemora team had the necessary equipment for design work on roads and bridges, but many of these tests were manual. As in any field, the higher the quality of the equipment, the more the expertise is appreciated. „You communicate differently with clients if you have technology behind you. All of us in the team took a qualification course to learn how to use the equipment. Being so valuable, there was a risk of damaging them. We remained good friends with the suppliers, helping each other on every occasion.” When asked if they would submit a second project, he answered without hesitation that European funds are a blessing for any business and that they are well-invested money that generates value. He will retire soon, but his daughter will undoubtedly continue down this path of European funding, especially since she has mastered this language perfectly.

Reporter REGIO is a North-East RDA initiative, which focuses on promoting the successful projects of our beneficiaries, projects that have managed to stand out by bringing added value and impact to the community. At a time when negative news predominates, we offer you beautiful but true stories for reading, meant to strengthen the belief that „it is possible”! Be part of the story!

Are you a Regio beneficiary? Let us tell you the story.

Contact us for details at info@adrnordest.ro

INTERES PUBLIC

INTERES PUBLIC