Reporter REGIO: episode 17

Evolution in the footwear industry with REGIO support

Success stories, possible with the support of Regio Nord-Est 2014-2020

In Vicovu de Sus, a town renowned nationally for its tradition of producing high-quality leather footwear, it is said that „if there’s a house where nobody makes shoes, you can be sure that in the second house, at least two people are skilled shoemakers„. This craft has been passed from generation to generation, and the techniques have been perfected with the help of technology over time.

Ady Star Shoes SRL is a footwear manufacturer and was among the first companies in Vicovu de Sus City to receive funding through the 2014-2020 Regional Operational Program (ROP) for the purchase of machinery. Today, the company enjoys success with two projects, one completed and one in progress. But it doesn’t stop here. There are two more projects planned: one on circular economy and another for the digitalization of the company. Thanks to European funding, Ady Star Shoes SRL invested in innovation, technology, and product development, managing to expand its production capacity and improve product quality. They have shifted from custom-based production to serial production, signifying a tremendous evolution for a small company. The two REGIO projects have a total value of 1,8 million euros, with non-reimbursable financial assistance of 1,1 million euros.

The craft has been passed down from one apprentice to another

The art of shoemaking in Vicovu de Sus started, it is said, with one person who knew this craft in the 1980s. This master became a true mentor to his apprentices, who learned alongside him for a year, gaining the knowledge and skills needed to become shoemakers themselves. After completing their apprenticeships, they would open their workshops and, in turn, become mentors to other apprentices, thus passing down the tradition from generation to generation. The production of leather footwear became an important phenomenon in Vicov at that time, flourishing and gaining respect in the community. Before the 2008 economic crisis, there were around 200 specialized firms in this industry registered with the municipality. After the crisis, the industry suffered a decline, and only about 50 firms managed to survive. Even so, at present, this cozy town in the Bucovina region produces around 8 thousand pairs of footwear per day.

Production, sales, and production again

Gheorghe, or George, as his friends call him, Ciubotar, was an apprentice in the 1990s. He learned the craft and then opened his workshop at home, like everyone else. He handmade shoes and sold them in markets and fairs. Despite his name, Ciubotar (shoemaker) laughs and says that nobody in his family was a shoemaker, and he did not inherit the trade. He was the first to practice this craft. After completing his military service, he took a break from production and shifted toward distribution. „I sold footwear in our bazaar in Suceava. I enjoyed it and liked it. At that time, many of those who produced didn’t know how to sell, and those who sold didn’t know how to produce. I had this advantage. A distributor would collect from 4-5 local producers and sell further. It was a profitable business. Now, I have my distribution network”, George says. He became an associate and administrator of Ady Star Shoes last year, transitioning from a distributor’s position. He had been closely associated with the company and was actively involved in the production process since its establishment in 2015.

The first REGIO project

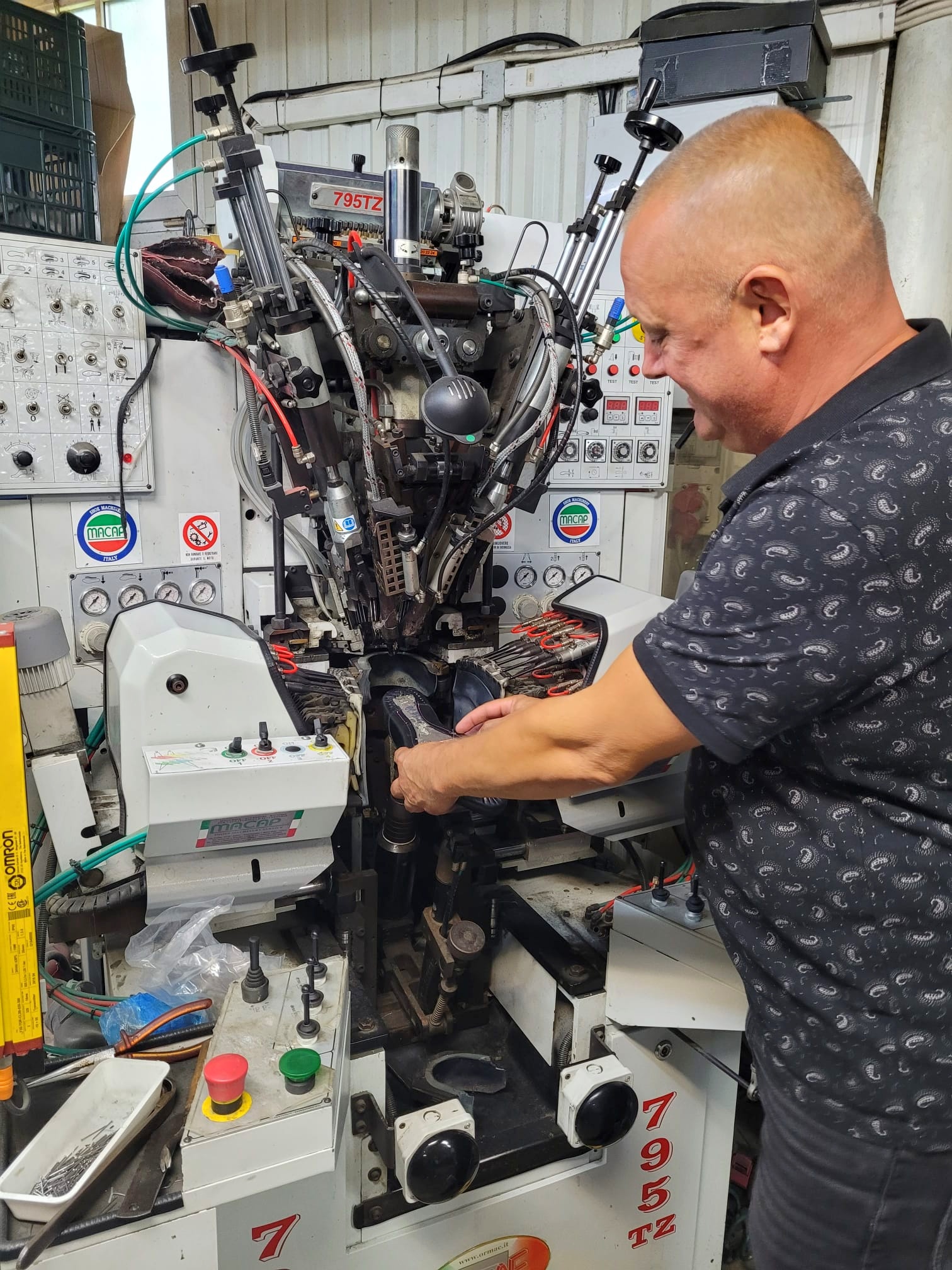

In 2018, the first project for advanced technology equipment for Ady Star Shoes was approved, with non-reimbursable funding of 178k thousand euros. „The company was quite small at that time. After the project was implemented, a significant difference was seen in both quality and quantity. Two machines were the main components: one for toe lasting and one for heel lasting, that’s what they’re called. After the machines arrived and the Italian manufacturer set them up, production increased from 20-30 pairs per day to 40-50 pairs per day. But, more importantly, we started to have serial production. Previously, production was based on orders received from distributors. After acquiring these machines, production became linear, with a constant flow and quality. The difference between custom-based production and serial production is a colossal step for any small company. We also saved a lot of time. What used to take half an hour, we can now do with the machines in 3-4 minutes. We needed these machines, and they helped us a lot”, says George Ciubotar.

Courage for the second project

Because the first project was completed in six months and went smoothly, George Ciubotar gained the courage to apply for a second project to expand production capacity. With the help of the consultant with whom he collaborated successfully for the first project, he planned a new hall with a 100% technologized production flow with the funding of the second project. A new space was needed due to increased capacity, along with the acquisition of new and efficient machinery. This second project has a total value of 1.5 million euros and is set to be completed by the end of the year. While the first investment ensured 75% technologized flow, with the remaining 25% still done manually, the second REGIO investment will achieve 100% technologized flow.

Care for employees and the environment: working with water-based latex

The second project includes a high-performance machine for applying heels, allowing the company to expand into the field of elegant footwear. A digital cutting table will eliminate the need for stamps and knives used currently, minimizing losses. Additionally, machines that work with water-based latex will be acquired. This is crucial for the environment, as the adhesives used in this industry are very toxic and harmful to the environment. „Using water-based latex has allowed us to be more mindful of the health and safety of our employees, as it poses fewer health risks compared to toxic adhesives. The value of the latex application machine is not very high, but the impact on the environment and health is colossal. At the same time, latex protects the interior of the leather from water. There are several benefits. Transitioning to working with water-based latex allowed us to adapt and stay in line with new industry trends, demonstrating that we can evolve and grow responsibly without compromising the quality of our products” says George. With the new project, Ady Star Shoes aims to reach a target production of over 100 pairs per day, and the new building has been designed accordingly.

Two more projects on the horizon

„If we complete this second project, we won’t stop there. I have great courage”, says George Ciubotar. His next goal is towards circular economy practices. Leather waste is challenging to recycle; it usually needs to be incinerated. With the help of high-performance machinery, losses from leather pieces are reduced, but they still exist. George and his consultant have ingeniously planned a recycling project. They believe it’s a waste that these leather pieces cannot be repurposed for other uses.

Furthermore, since there are funds available for digitalization, George wants to acquire some expensive footwear design applications. Currently, the design is done by an engineer. He creates the patterns, and the salesperson presents them to customers who then place orders according to their preferences. For inspiration, they also look at designs online. However, having some applications would be extremely helpful. Additionally, he aims to acquire a 3D scanner for shoe lasts, management, HR, accounting, and distribution applications. All of these would lead to the growth and expansion of the company—with the help of European funds and a touch of courage.

Reporter REGIO is a new North-East RDA initiative, which focuses on promoting the successful projects of our beneficiaries, projects that have managed to stand out by bringing added value and impact to the community. At a time when negative news predominates, we offer you beautiful but true stories for reading, meant to strengthen the belief that „it is possible”! Be part of the story!

Are you a Regio beneficiary? Let us tell you the story.

Contact us for details at info@adrnordest.ro

INTERES PUBLIC

INTERES PUBLIC